When your vehicle's ADAS systems aren't performing correctly, how do repair shops determine if calibration is actually necessary? Unlike traditional mechanical issues that are often visible or audible, ADAS problems can be subtle and intermittent. A sensor might be slightly misaligned without triggering obvious warning signs, yet still compromise your safety. Understanding the diagnostic process helps you make informed decisions about your vehicle's maintenance and safety. Here's what happens behind the scenes when technicians evaluate whether your car's safety systems need recalibration.

Advanced Diagnostic Equipment

Computer System Analysis

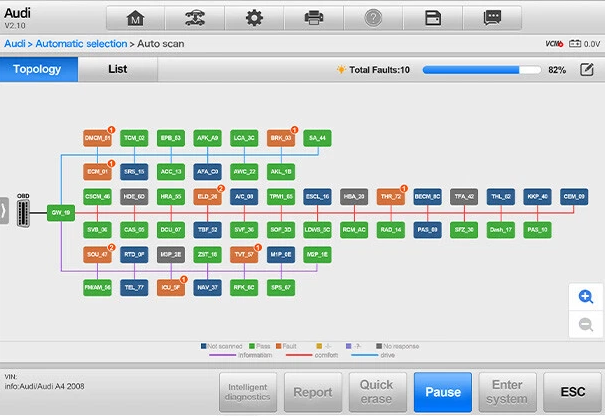

Modern diagnostic scanners can communicate directly with your vehicle's ADAS modules, reading error codes and system parameters that aren't visible to drivers. These tools reveal intermittent faults, sensor drift, and calibration values that have shifted outside manufacturer specifications. The diagnostic process often uncovers problems that haven't yet triggered dashboard warnings. When you purchase a diagnostic scanner such as the Autel MS909, the Topdon Phoenix Smart, or the Launch Tech X431 Turbo III, these tools perform this analysis.

Real-Time System Monitoring

[Image by Autel linked to their website via https://www.autelsale.com/upload/pro/24041717134064227260.jpg]

Professional equipment can monitor ADAS performance in real-time, tracking how sensors respond to controlled inputs. This testing reveals inconsistencies in sensor readings, timing delays, or accuracy issues that indicate calibration problems. These tend to be more specialized equipment focused on the specific ADAS modules. Autel’s Live Data Fusion brings these capabilities together by adding live data from multiple systems and sources into one single interface. Check out Autel’s new updates on Live Data Fusion and their supported vehicles here.

Physical Inspection Methods

Experienced technicians perform detailed visual inspections of ADAS components, looking for signs that a calibration may be compromised:

- Sensor alignment checks - Measuring precise angles and positioning

- Mounting bracket integrity - Ensuring sensors haven't shifted from impacts

- Lens and sensor cleanliness - Confirming optimal detection capability

- Wiring harness condition - Checking for damage affecting sensor communication

Documented Service History

Reputable shops review your vehicle's service records to identify situations that automatically require calibration. Recent windshield replacement, collision repairs, or suspension work create mandatory calibration needs regardless of current system performance. A documentation-based approach helps shops justify the calibrations that they perform.

Manufacturer Guidelines

Professional shops follow specific manufacturer protocols that define when calibration is required. These guidelines are based on extensive testing and legal safety requirements. Shops access technical service bulletins, recall notices, and updated calibration procedures that determine necessity based on your vehicle's make, model, and year.

Pre and Post-Repair Testing

Before Work Begins

Legitimate shops document current system performance before any work, creating baseline measurements that prove calibration status. This documentation protects both you and the shop by establishing exactly what calibration issues existed initially.

Verification After Service

Following calibration, professional equipment verifies that all systems meet manufacturer specifications. This post-service testing proves the calibration was successful and your safety systems are functioning properly.

Why Documentation Matters

Trustworthy repair shops provide detailed reports showing diagnostic findings, calibration measurements, and verification results. This documentation serves multiple purposes:

- Insurance claims - Proving calibration necessity for accident-related repairs

- Warranty protection - Maintaining manufacturer warranty compliance

- Safety assurance - Confirming your vehicle meets safety standards. These are confirmed through precise calibration procedures that ensure cameras, radar sensors, and other safety systems function within exact manufacturer specifications. Read about the long term cost and safety impacts of ADAS calibration.

- Resale value - Demonstrating proper maintenance history. Keep all documents and have them accessible for proof of value.

The Cost of Proper Diagnostics

Professional ADAS diagnostics require significant equipment investment and specialized training. While this adds to service costs, it ensures accurate diagnosis and prevents unnecessary work. The investment in proper testing equipment demonstrates a shop's commitment to quality service and customer safety.

Check out our YouTube channel on our latest episodes with NEX Auto and how they document ADAS services from start to finish.