Your calibration report is your key to insurance approvals, your shield in court, and your proof of professional competence all wrapped into one document. Get it wrong, and even perfect calibration work can come back to haunt you. Get it right, and you've got bulletproof protection that keeps everyone happy.

The Anatomy of Protection

Every bulletproof calibration report has five critical components that work together like layers of armor. Miss one layer, and you've got a weak spot that sharp lawyers and skeptical insurance adjusters will find faster than you can say "lawsuit."

Layer 1: The Foundation Story Start with WHY calibration was needed. Was it accident damage? Windshield replacement? Manufacturer requirement? This isn't just background information – it's the legal justification for every dollar spent on calibration work.

Opening Moves That Matter

Vehicle Identification Beyond the Basics Sure, you need VIN, make, model, and year. But bulletproof reports go deeper. Include production date, option codes, and ADAS package details. Why? Because a 2023 Honda Accord LX has different calibration requirements than an EX-L with Honda Sensing Elite. Those details matter when lawyers start asking questions.

The Trigger Event Documentation Here's where most reports fall apart. Don't just write "collision repair" or "windshield replacement." Paint the complete picture: "Front-end collision damaged radar mounting bracket, requiring bracket replacement and subsequent radar calibration per Honda Service Bulletin 19-038-01."

Pre-Calibration Intelligence Gathering

Smart technicians document what they find BEFORE touching anything. This detective work becomes crucial evidence later.

Visual Inspection Results - Photograph everything, but organize photos systematically. Wide-angle shots showing overall vehicle condition, medium shots of sensor locations, close-ups of specific damage or misalignment. Include timestamps and multiple angles – they're harder to dispute than single photos.

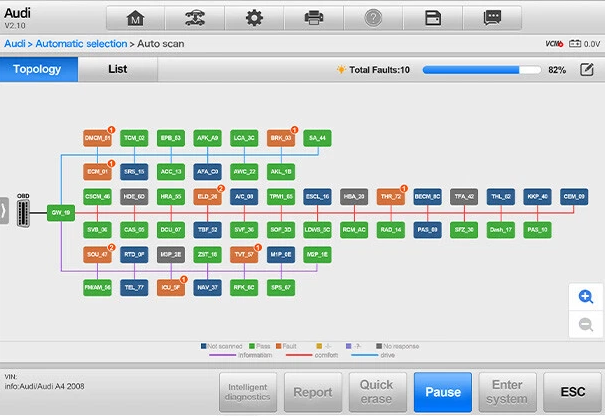

Diagnostic Code Analysis - Don't just list codes – explain what they mean. "B2141-15 Present" tells lawyers nothing. "B2141-15: Front radar sensor alignment out of specification, indicating sensor position shifted beyond acceptable parameters" tells the whole story.

Baseline Measurements - Record current calibration values before starting work. These numbers prove the system was actually out of specification, not just receiving "routine maintenance." This data transforms your calibration from optional service to necessary repair.

DTC Pictures - This may seem too easy, but include DTC screenshots of before (and after).

The Calibration Process Chronicle

Document your work like you're teaching someone to repeat it perfectly. This level of detail serves two purposes: it proves you followed proper procedures, and it demonstrates professional competence.

Environmental Conditions - ADAS calibration requires specific conditions that affect accuracy. Record lighting conditions and floor surface details. When someone questions calibration accuracy six months later, this data proves you worked within proper parameters.

Equipment Documentation - List every tool used. Your $50,000 calibration system is there for a reason.

Don't forget to screenshot DTC codes from your pre-scan!

The Numbers Game

Before and After Values

This is where your report becomes bulletproof or worthless. Document specific calibration values before work began, target specifications from manufacturer data, and final achieved values after calibration completion.

If your scan tool provides before/after calibration values, include them. If not, document the system’s pre-calibration status (e.g., DTCs, ‘Not Calibrated’ indicators), and record the post-calibration confirmation screen. Screenshots, printed reports, and data exports should be attached as supporting documentation whenever possible.”

Present this data clearly: "Front radar horizontal alignment: Initial value -2.3°, Target specification 0° ±0.5°, Final calibrated value +0.1°." These numbers tell an undeniable story of necessary work properly completed.

Tolerance Documentation

Include manufacturer tolerance specifications in your report. This proves your calibration meets professional standards, not just "close enough" estimates.

For example:

Radar Horizontal Angle

Initial: -2.3°

Final: +0.1°

OEM Spec: 0.0° ± 0.5° ✅

Quality Verification That Counts

Test Drive Results Static calibration is only half the story. Document how systems perform during actual driving conditions. Record specific tests performed: lane keeping assist response, adaptive cruise control operation, automatic emergency braking sensitivity checks.

System Response Testing Professional reports include controlled testing results. How does the forward collision warning respond to test targets? Does lane departure warning activate at proper line crossing angles? This functional testing proves your calibration actually works.

For example:

System warned at ~0.5 ft line crossing during 45 mph gentle drift across centerline.

Audible + steering vibration alert present.

✅ LDW response verified.

Customer Communication Integration

Plain English Explanations Technical accuracy matters for legal protection, but customer understanding builds trust. Include a summary section explaining what was done and why in language customers can understand and share with their insurance companies.

Visual Evidence for Customers Before and after photos serve double duty – legal protection for you, peace of mind for customers. Show them the difference between misaligned and properly calibrated systems.

The Insurance-Friendly Format

Claim-Ready Language Structure your report sections to match insurance claim requirements. Use headers like "Necessity Justification," "OEM Compliance," and "Quality Verification" that adjusters recognize and approve quickly.

Cost Justification Details Break down calibration costs by system and procedure. This transparency prevents "all-or-nothing" disputes where insurance companies try to deny entire claims over single line items.

Chronological Organization Organize information in timeline order: initial inspection, diagnostic findings, calibration procedures, verification testing, final results. This logical flow makes reports easier to follow and harder to challenge.

Professional Presentation Use consistent formatting, clear headers, and professional language throughout. Reports that look professional carry more weight in legal and insurance situations.

Digital Integration Advantages

Automated Data Collection Modern calibration equipment can export data directly into report templates, reducing transcription errors and saving time. Configure your equipment to capture all relevant data points automatically.

Cloud-Based Storage Store reports in searchable, backed-up systems. When that insurance question comes up two years later, you need instant access to complete documentation.

Integrated Software Solutions Certain software systems are sprouting up to solve the problem of designing integrated reports. Check out ADAS Trak as a forthcoming solution, or Revv as another.

The Three-Year Test

Build every report like you'll need to defend it in court three years from now. Will you remember the details? Can you prove what you did and why? Does the documentation stand alone without your memory filling in gaps?

Your calibration work protects lives on the road. Your calibration report protects your business and reputation. Both deserve your absolute best effort.

Check out our latest YouTube videos with NEX Auto on How to Build Stronger Insurance Relationships in ADAS Calibration.